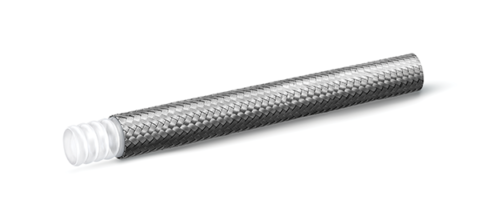

VHP PTFE Flexible Hoses for very high pressures

VHP PTFE Flexible Hoses for very high pressures are part of our range of products that can be used in critical high pressures applications due to their high-performance’s constructions.

- Information

- Materials

- Industries

- Quote and samples

- Related Products

VHP PTFE Flexible Hoses for very high pressures

VHP PTFE Flexible Hoses stand out in two different types:

VHP 1AB Range – VHP PTFE Flexible Hoses with single aramid fibre braid

VHP 2AB Range – VHP PTFE Flexible Hoses with double aramid fibre braid

COSTRUCTION

Internally the hose consists of a natural or conductive PTFE core tube.

Externally the hose is reinforced with a single or double braid in aramid fibre and with a single wires braid in stainless steel AISI 304 HD.

APPLICATIONS

VHP PTFE Flexible Hoses are the ideal solution for applications where it’s required: resistance to very high pressures, long durability and chemical resistance.

ASSEMBLY

As specialists in all aspects of PTFE, we provide a high standard of quality of PTFE flexible hoses, assembled and tested according to UNI EN ISO 1402, our own specifications and on demand according to customers’ specifications.

Our proposal includes:

the assembly of our complete range of PTFE Flexible Hoses, Convoluted PTFE Flexible Hoses with flared/tafted ends, PTFE Convoluted Tubing with vacuum wire, PTFE Convoluted Tubing reinforced with sock braids in AISI304, AISI316, polypropylene, PVDF or glass fibre-silicone sleeve.

Wide range of accessories: fittings, ferrules, flanges, whip-check safety cables, fluoropolymer lined fittings.

Quality: pressure tests, burst pressure tests and related certifications.

Material: Polytetrafluoroethylene/PTFE

The streight of the carbon-fluorine bond and the high atomic weight give PTFE exceptional and unique properties and characteristics.

First of all temperatures resistance: PTFE can work in continuous both in high temperature applications up to 260°C (500°F) and in applications at low temperatures up to -70°C (-94°F), without loss of physical properties.

In addition to the remarkable thermal stability, PTFE has an almost absolute chemical resistance.

PTFE almost total chemical inertia can be attacked only by a few chemicals and only under certain conditions of high temperature and pressure.

PTFE also offers the following properties and characteristics, so far have not found in any other plastic material:

| Longer flex-life | Excellent dielectric characteristics |

| UV Rays resistance | Aging resistance |

| Weather resistance | Any hygroscopicity |

| Non-toxic and suitable for food contact | Self-lubricating and non-sticking |

| Non-inflammable | Good resistance to fatigue and shocks |

CUSTOMIZED TECHNICAL SOLUTIONS

All PTFE Flexible Hoses can be customized according to customers’ specifications or depending on application’s critical issues.

PTFE Flexible Hoses can be customized with reinforcement in AISI 316 HD and also with protection braids in polypropylene, fiberglass, polyester and PVDF.

PTFE Flexible Hoses can be protected also co-extruding a cover on the wires braid.

Here below some examples of covers:

PVC: facilitates the cleaning of the hose, has a wide range of colours, traceability marking.

Silicone: resists up to 200°C, resists aggressive environments, improves the flexibility of the tube, has a good range of colours.

Hytrel®: resists abrasion, improves hose flexibility, facilitates cleaning of the hose.

Other possible covers: PA11, PA12, TPE, TPU.

Industries

The VHP PTFE Flexible Hoses for very high pressures are used in the following industries:

Quotes/Samples

Fill out the form below to request quotes and samples.